Copy of PROCESS

How we make chocolate in Alkimia to preserve and highlight the unique flavors of each cacao fruit.

1. Direct Trade

We build a good relationship with local dedicated farmers from Peru who have been growing cacao with detailed attention to their cultivation and fermentation. We pay them a premium price for their cacao.

4. Cracking and Winnowing

We remove the shell off the beans and keep only the meat, the nibs, which are the only part of the cacao that’s used to make chocolate.

7. Packaging

We unmold them and wrap them in foil by hand. We put them, in their hexagonal boxes and they are ready for you to enjoy.

2. Selecting Bean

To begin our process we hand-sort our beans and removed any cracked or poorly fermented beans.

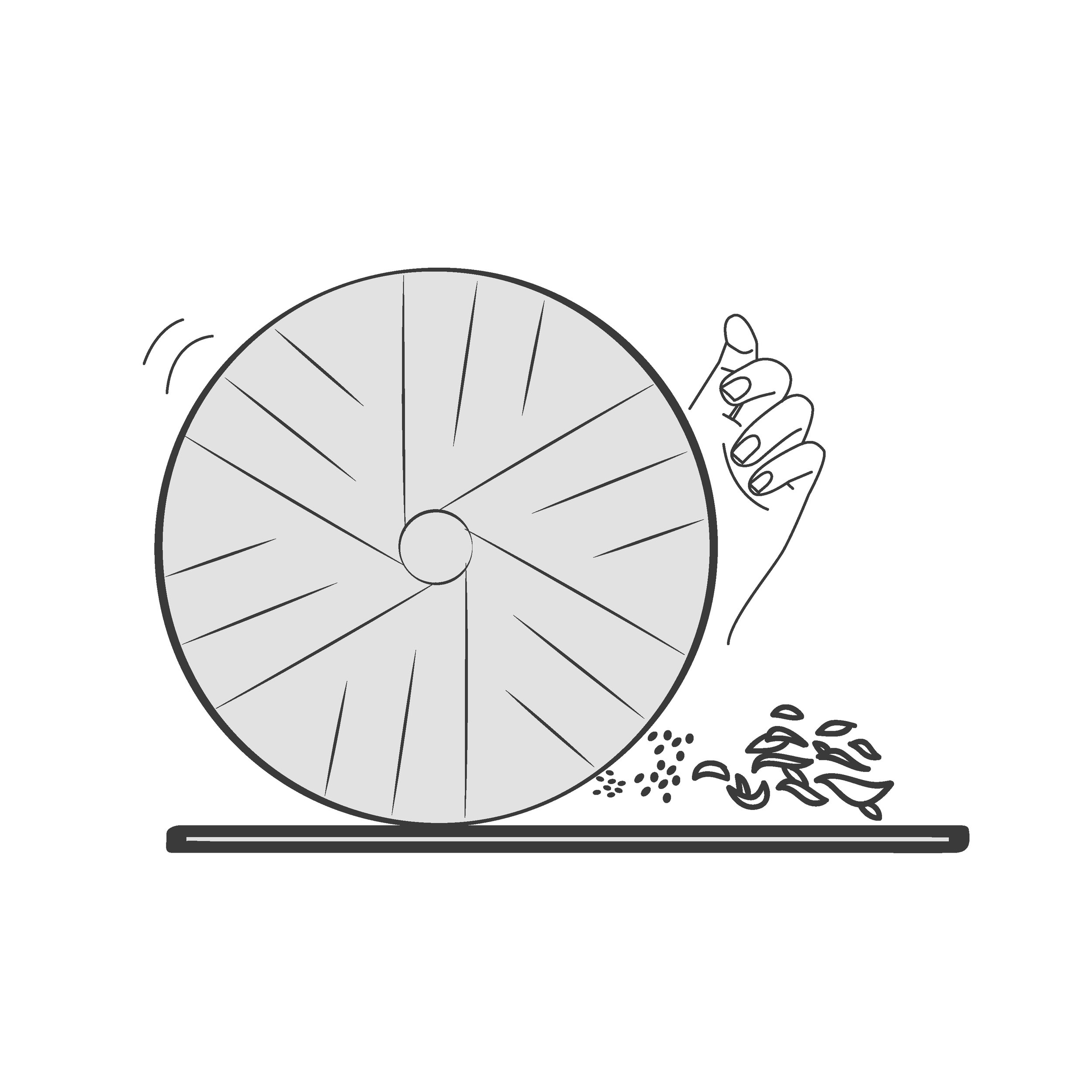

5. Stone-grinding

We stone grind our nibs together with the sugar in a melanger (a stone roller machine) for 3 days until they become liquid.

3. Roasting

We roast our beans at low temperatures to preserve all the flavors and nutritional value of the beans. We care about the environment, our roaster has a very low environmental footprint.

6. Tempering and Moulding

When the chocolate is completely liquid we temper it by heating, cooling and agitating it to form the right type of crystals. This makes the chocolate become smooth, shiny and have a “crack” sound when it breaks. When we arrive to the right temperature we set the chocolate into the molds and let them cool until they become solid and are ready to unmold.